A renovation that proves bamboo belongs everywhere — even on the open road.

Some projects stop us in our tracks. When we received a set of photos from Dan Innes of Zone2 Joinery, showcasing a full bus renovation using our bamboo panels, we knew this one needed to be shared. Thoughtfully designed and built with care, this project highlights just how versatile bamboo can be in the hands of a skilled craftsman. Dan kindly walked us through the process, the thinking behind each detail, and how bamboo helped bring this unique fit-out to life.

Here's his story:

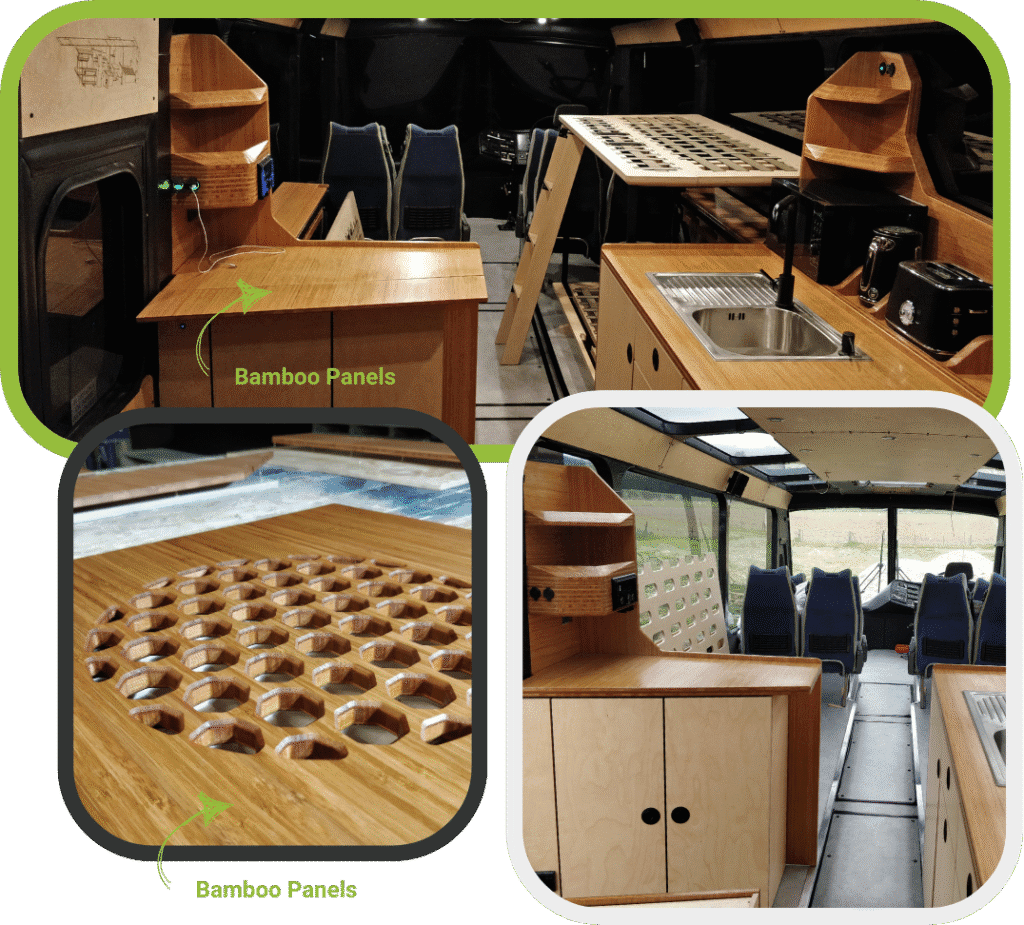

In 2020 whilst embarking on an epic 12 meter Volvo B10 bus interior design and build project we came across Plantation Bamboo’s panel products and decided they’d be the perfect fit to make the project pop!

We were extremely impressed with how nicely it held crisp details during CNC machining processes due to its high density and overall consistency. We knew we were going to need a good handful of sheets on this project and we were happy when all the panels provided by Plantation Bamboo arrived in mint condition.

We achieved a silky smooth surface with intricate effects from stacking up layers of the coffee panel, sanding down to 320grit, further staining it with a Cabots oil based stain and finishing with thin layers of danish oil, brushing on-wipe off. We’d machined in pockets for locating dowels between the layers so they wouldn’t slide around on the glue while clamping.

Using this method of finish consistently on worktops, shelving & special features throughout the whole interior really tied the whole thing together and sets a calm, modern and organic mood.

Plantation Bamboo panels also look great next to our powder coated custom designed and fabricated mechanical furniture pieces and also as the material for control housing surrounds and switch-plates. It laser engraves very nicely as displayed on this bathroom switchplate.

At Zone 2 we specialise in ultra custom purpose designed & engineered interiors with fully integrated off grid systems. Each project is executed as a functional piece of engineered art.

The cabinet above the entry stairs has an extendable worktop that can be used as a stand up desk utilising the steps to create different desk heights.

The bus has a sloping floor and ceiling at an angle of 3 degrees and so all the cabinets were built with a sloping floor and level worktops. To dance with this challenge we then made the splashback slope 3 degrees in the other direction and added angled faces to the shelf edges.

Closing of the master bedroom at the rear was achieved with this half height cavity slider and a door that when open blends invisibly into the wall. The cavity slider runs on an angled track as the roof of the bus is curved therefore its higher in the middle than it is at the sides.

We designed it this way to keep a clean, full-length ceiling line and create a wider doorway area, improving the overall flow and feng shui of the space.

As the door swings over the walkway to close off the bedroom a panel of flooring slides down from the inside of the door to close the gap in the walkway. Turning the ultra flush custom door handle lifts this back up and clips it in place when you open the door

The bus is designed to sleep 7 people and has 2 couches that unfold into bunk beds that have ladders folding out of them also. The ladders can move back and forth along the front edge of the bunks so as not to interfere with each other. The 5th bed is created by lowering the dining table to the level of the seats and of course there’s plenty of room for two in the master bedroom.

If you want to read more about this project and others please visit this link to our website as we have a full and detailed write up with plenty of pictures for you to enjoy: www.zone2.nz/chris-mannings-volvo-b10

Cheers!

Dan from Zone 2

PS. We are now taking applications for our 2026 build slot 😉