Good stock available in our Auckland & Christchurch warehouses - order now!

Sustainable & Durable Bamboo X-treme Cladding

Our Bamboo X-treme Cladding has been tested and appraised by BEAL as compliant with the New Zealand Building Code

Plantation Bamboo X-treme Cladding is an extremely strong, solid, high-density exterior bamboo plank made from compressed strand-woven bamboo.

Summary of Key Advantages:

Click to expand...

Thermally modified and compressed bamboo ensures exceptional hardness, stability, and resistance to warping, cracking, or splitting over time.

Made from fast-growing Moso bamboo, it’s one of the most eco-friendly cladding materials available, with multiple sustainability certifications and a low carbon footprint.

Achieves high fire safety ratings (including Class B-s1-d0; EN 13501-1), making it suitable for fire-prone and commercial zones where other timber products may not qualify.

Requires less upkeep than many hardwoods. It can be oiled for a rich, maintained look or left to naturally silver—with a lovely bamboo grain—without compromising performance.

Manufactured to tight tolerances with minimal knots or variation, delivering a sleek, modern finish ideal for architectural applications.

Installs using common woodworking tools and hidden fastener systems, allowing for quicker, cleaner installs compared to many composite or hardwood boards.

Offers the warm, rich aesthetic of timber with superior resistance to moisture, fungi, and insects—ideal for harsh climates.

Backed by a 25-year warranty for peace of mind, supported by global use in demanding exterior environments by our Dutch supplier.

A special, patented “thermo-density” heat treatment manufacturing process provides Bamboo X-treme Cladding with the highest durability class possible, making it well-suited for the harsh New Zealand sun and environment.

Why Choose Bamboo X-treme Cladding?

The Bamboo X-treme cladding system is a durable and sustainable alternative to timber hardwoods and other cladding options, and is successfully used in Europe and around the world. Our supplier utilises a 200°C heat-treatment process to thermally modify the bamboo to increase the stability, hardness and density of the cladding boards, making the cladding suitable for very demanding applications.

With the strong stability of this product, it can withstand temperature changes with hardly any shrinking or swelling. Due to this stability, the cladding will stay flat and in place, unlike some other natural materials.

The bamboo cladding is fixed to cavity battens (with the clips/screws provided), over a waterproof rigid or flexible air barrier membrane (RAB/FAB) – as a cavity system. Please see the Technical Manual (link below) for the specifications, drawings and installation instructions.

The cladding can also be used for making a fence, feature wall and more!

For pricing, free quotes and further information, please contact us or request a FREE sample

★★★★★

“Plantation Bamboo and Ingrid were fantastic to deal with on our project. We made the change to bamboo from cedar and are so glad that we did. We will definitely use this product again. Thanks!”

– Mavora Homes Ltd, Southland, NZ

Install Cladding Quickly & Economically

Bamboo X-treme cladding comes with powder-coated stainless-steel clip and screw fixings, which makes installation easier and provides a smarter finished look.

The clips are simply screwed onto battens and the cladding boards clip together with the boards only requiring to be cut at the end of a row (as the ends snugly fit together). See our installation instructions for more information.

After installation, the cladding does not require any regular maintenance (unless a darker colour is desired), which can save on time and cost. Due to the “thermo-density” heat treatment process, the cladding is a mid-dark brown colour, but this will gradually change to a silver-grey colour over time as it naturally weathers.

Sustainable Choice

While tropical hardwoods can take up to 80 years to grow to full maturity and be ready for harvesting – Moso bamboo stems (which is what bamboo X-treme cladding is made from) are mature after 4-5 years.

After harvesting the bamboo stem doesn’t die and no deforestation occurs – the rhizomes sprout new shoots even faster. There, the bamboo forest can be harvested annually and sustainably in a fair-trade manner for the farmers, by default.

All our solid bamboo products have a negative carbon footprint over their complete lifecycle (see here for more details.

Fire Safety

Contrary to many other wood products, bamboo X-treme cladding reaches a fire safety class B-S1-d0 (EN 13501-1) and Class A (ASTM E84). This makes it suitable for commercial buildings, apartments and housing while giving a beautiful natural appearance.

The cladding reaches this exceptional fire safety rating without impregnation of eco-damaging and expensive fire retardants. Therefore, the cladding is safe for the environment and for the installers. Sustainable, safe and beautiful!!

Product Specifications and Instructions

Explore installation, sizing and general product info below.

Bamboo x-treme cladding boards are 1850mm long, with end-matching tongue-in-groove join. The boards are 137mm wide, but with the profiled overlap the visible face is 128mm (once clipped together and installed), with a small gap provided between the boards for air-flow.

The cladding is 18mm thick.

There are 5 boards = 9.25LM per box. A box weighs 27kg.

Supplied with powder-coated stainless steel clip and screw fixings (2 x 50mm screws per clip) – for “invisible” fastening.

Technical characteristics and certifications of bamboo x-treme cladding:

- Density: +/- 1150 kg/m3

- Dimensional stability: length: + 0.1 %; width: + 0.9% (24 hours in water 20°C)

- Resistance to Indentation – Brinell Hardness: ≥ 9.5 kg/mm2 (EN 1534)

- Reaction to fire: Class B-s1-d0 (EN 13501-1) 1)

- Flame spread index: Class A (ASTM E84)

- Thermal emittance: 0.81 (ASTM C1371) 2)

- Solar Reflectance (SR): 0.32 (ASTM C1549) 2)

- Solar Reflectance Index (SRI): Low 27, Medium 30, High 33 (ASTM E1980) 2)

- Modulus of Elasticity: 13565 N/mm2 (mean value – EN 408)

- Bending strength: 54.4 N/mm2 (characteristic value – EN 408)

- Biological durability: Class 1 (EN 350 / CEN/TS 15083-2), simulated graveyard test / Class 1

- (EN 350 / CEN/TS 15083-1)

- Effectiveness against Blue Stain: Class 0 (EN 152)

- Use Class: Class 4 (EN 335)

- CO2 neutral: LCA report TU Delft (ISO 14040/44) (www.moso-bamboo.com/lca)

- Environmental Product Declaration – EPD (EN 15804) (www.moso-bamboo.com/epd)

- Contribution LEED BD+C – v4: MR 1, MR 2, MR 3 (FSC®), SS 7

- v2009: MR 6, MR 7 (FSC®)

- Contribution BREEAM: MAT 1, MAT 3 (FSC®), MAT 5 (HD)

- Warranty: 25 years

1) Tested on 18 mm thickness, without gaps between boards, with ventilation space behind boards.

2) Tested on 3 year-weathered Bamboo X-treme Cladding

Learn all about Bamboo X-treme, from our Dutch supplier, MOSO Bamboo

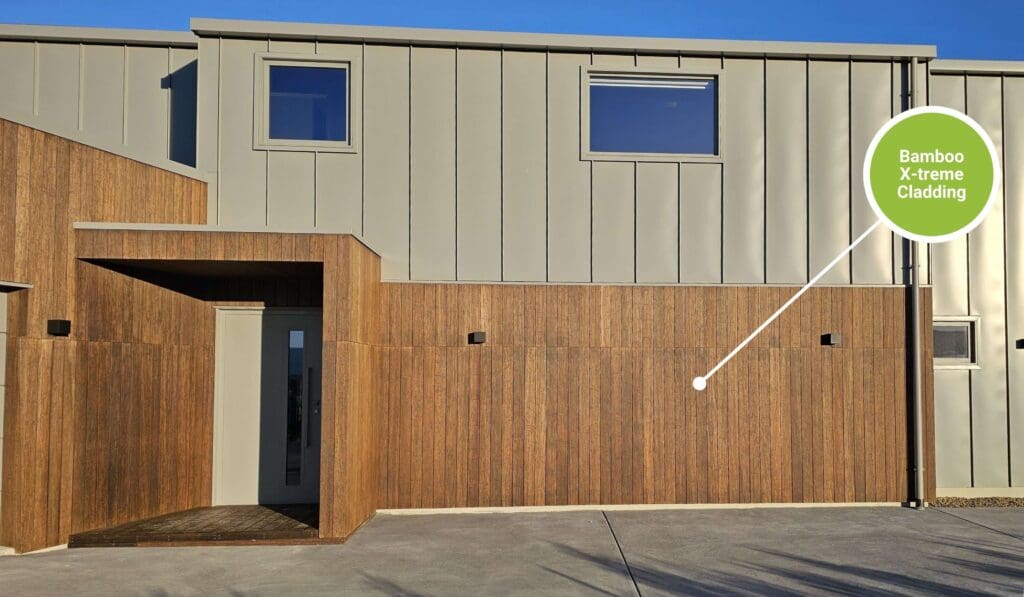

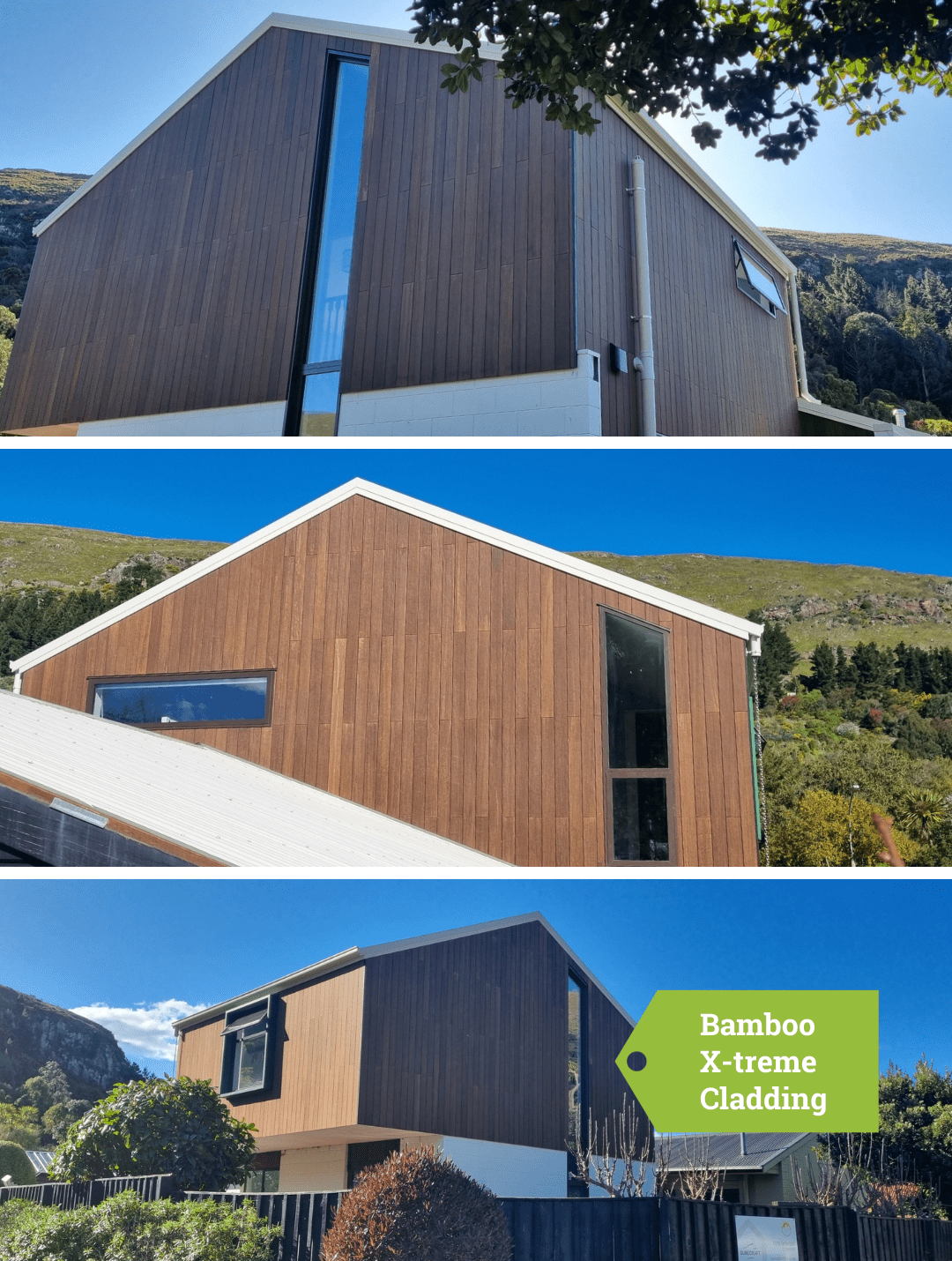

Explore Our Bamboo X-treme Cladding Gallery

We have so many amazing images from projects over the years, truly showcasing what our bamboo product can do.

FAQ's

We’ve addressed the most frequently asked questions about our bamboo cladding. Still have a question? Contact Us >

Some handy installation tips on a house re-clad from a builder, Elite Deck & Fence Co, Kapiti Coast.

More reasons to choose Bamboo X-treme Cladding

Bamboo X-treme Cladding is a durable and sustainable solution for exterior walls, offering long-lasting performance, design flexibility, and a refined, modern finish.

Crafted from rapidly renewable Moso bamboo (the giant bamboo species), which fully matures in 4-5 years, the product has a negative carbon footprint over its lifecycle, making it an environmentally responsible choice.

The patented Thermo-Density heat treatment process enhances the cladding’s stability, reducing the risk of warping or movement over time.

Designed for flexibility, the cladding boards can be installed vertically or horizontally, to suit various design preferences. Builders can also make boxed-corners, edging , scribers, etc from the cladding boards (they cut cleanly and machine well)

Backed by a 25-year structural warranty, ensuring confidence in its long-term performance (also backed by our Dutch supplier, MOSO Bamboo). The bamboo cladding has been consented by many Councils all over New Zealand.

Independently tested and appraised by the Building Element Assessment Laboratory (BEAL), the Bamboo X-treme Cladding system complies with the New Zealand Building Code clauses B1 (Structure), B2 (Durability), E2 (External Moisture), and F2 (Hazardous Building Materials).

It's not just us that LOVE Bamboo!

What customers are saying about our bamboo cladding...

Builders love it!

Christchurch Builder, Matty from Surecraft Carpentry installed bamboo x-treme cladding on an architectural second story house addition.

"It's the first time I've heard about a T&G cladding system. It's amazing how dense and versatile this cladding is - it doesn't dent like cedar which makes installation much easier. It seems bulletproof. It saved me a lot of time having the hidden clip and screw fixings and looks very smart with clean lines, once installed. I'm looking forward to using it again."

+ Matty, Surecraft Carpentry, Canterbury

What our customers are saying in Google reviews...

Frequently Asked Questions

We answer the most popular questions asked about our Bamboo X-treme Cladding System.

Still have a question? Contact Us >

General

Yes, our bamboo X-treme cladding has been tested and appraised against the NZ building code by BEAL (Building Element Assessment Laboratory). BEAL is a recognised testing authority that tests and appraises the compliance of many building products against the NZ building code requirements (equivalent to a BRANZ appraisal).

The BEAL certified Appraisal Certificate confirms that the Plantation Bamboo X-treme Cladding System, when designed, installed and maintained as per our technical manual will meet the following NZBC required clauses:

Clause B1 Structure

Clause B2 Durability

Clause E2 External Moisture

Clause F2 Hazardous Building Materials

There are various options for certification to meet the NZ Building Code requirements. The bamboo X-treme cladding is not Codemark certified – however it’s been fully tested and appraised against the NZ Building Code to meet the required building standards (E2, B2, B1 and F2) – as per the BEAL Appraisal Certificate. The cladding has been consented by many Councils and BCA’s all over NZ.

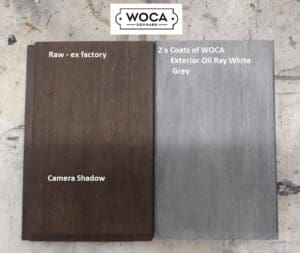

Bamboo X-treme cladding is only available in one, natural colour (as per the FREE sample available). Over time it will naturally weather and the colour will lighten (like most timbers). As it weathers the attractive natural bamboo grain becomes more apparent. Some people like this ‘weathered look’ and choose to leave it like this – unfinished.

If a darker colour (or different colour – there are many available) is preferred, maintenance can be carried out with a pigment coloured WOCA oil (or similar) to enhance the cladding to a colour of choice. Therefore, there are many colouring options available. Here is an example of the cladding with a grey WOCA oil applied:

Bamboo x-treme cladding often only requires 3-5% wastage as all boards are straight and uniform in size – some other timber decking options can require 10-30% wastage due to warps in boards, knots in the wood, not being straight, etc.

No, one of the many benefits of the bamboo X-treme cladding is that it’s considered low maintenance, as you can just leave it to weather naturally without the need to finish (oil/stain) it. The cladding comes unfinished and can be left this way, or it can be oiled to a preferred colour when installed, or at a later time by applying a pigmented oil.

The cladding will gradually turn more of a silver/grey colour over time as it weathers in the sun – and the attractive bamboo fibres will become more noticeable. However, if this natural look is not desired the cladding can easily be oiled to a colour of choice.

Unlike cedar (or other timbers), which can show dark mildew and require a lot of cleaning and maintenance, bamboo X-treme cladding has been through a Thermo Density heat treatment process, which helps prohibit these issues and extra maintenance requirements.

Contrary to many other wood products, bamboo X-treme cladding reaches a strong fire safety class of B-S1-d0 (EN 13501-1) and Class A (ASTM E84). This makes it suitable for commercial buildings, apartments and housing while giving a beautiful natural appearance.

The bamboo cladding reaches this exceptional fire safety rating without impregnation of eco-damaging and expensive fire retardants. Therefore, the cladding is safe for the environment and for the installers.

The bamboo X-treme cladding is currently available in the one profile (1850 x 137 x 18mm – with a 128mm visible face once installed with clips/screws in a shiplap profile). Every board is consistent in size and length – without the bowing/warping experienced with many timber products, resulting in minimal wastage.

While the cladding is shorter than some timber/other options, it has a unique tongue-in-groove join on the ends of the boards – providing a nice, tidy join and seamless finish with the invisible clip and screw fixings supplied with the cladding.

All of our bamboo products (decking, cladding and flooring) are manufactured at one, standard length (1.85m lengths). This is due to it being made from long bamboo fibres. To get the same consistency with the bamboo fibres/ thickness the farmers (and factories) cut the bamboo in this length.

The cladding comes in one easy to install ‘shiplap’ profile and can be installed both vertically and horizontally.

With vertical installation, the cladding can be installed either ‘stacked’ or ‘staggered’. If stacked with an uncut board-to-board join, there will be a neat line where all the boards join. If staggered, you can create a pattern with the boards, with either one full, one half board or another pattern if installed over a bigger area (within the guidelines for batten fixing).

- The “invisible” clip and screw fixings provided (included in the price) make for a faster and seamless installation process over many other cladding boards – as you don’t need to screw through the cladding, match ends, or cut off bowed/warped pieces, resulting in less cutting and wastage

- Since the cladding has been heat treated (via the patented “Thermo Density” process) you don’t get the unsightly mildew and mould like you often see with cedar cladding. As the bamboo X-treme cladding weathers, its beautiful grain will become more visible, which is a feature (rather than a bland grey fade, as with some other timbers)

- Due to bamboo X-treme cladding’s stability, unsightly gaps are not likely to open up, nor will the boards warp or buckle. The cladding is heavy, dense and has a real quality feel to it

- No excessive bleeding or leeching like some other timber cladding options.

- Being bamboo (and the fastest growing plant in the world), it’s an eco-friendly, sustainable cladding option. The Moso (giant) bamboo species from which the cladding is made only takes 3-5 years to grow to full maturity, enabling the stems to be harvested annually in many cases

- The bamboo X-treme cladding comes with a 25 year warranty

- No pre, or ongoing oiling and maintenance is required – unlike some other cladding options that require regular oiling, staining or painting (unless a colour change is preferred, which can be carried out with a pigmented oil colour of choice)

- Bamboo X-treme cladding performs well in all climates (both hot and cold), including areas such as central Otago, coastal salty regions, the west coast and far north, etc

- Bamboo X-treme cladding is suitable for extra high wind zones (55m/s) – in accordance with the NZBC.

Here is a short and interesting video (3 min) showing how bamboo X-treme cladding is made and why it’s such a fantastic, sustainable and durable cladding option – see video

Some refer to bamboo X-treme cladding as a “rainscreen” – however, it is better referred to as a “cladding system” or bamboo weatherboard, as the cladding is installed over a cavity system (like many other modern cladding options) with a batten on top of a weathertight rigid or flexible air barrier (RAB or FAB). This cladding system provides a double layer of protection against the weather.

There is a small gap between the cladding boards (that the clips provide), which provides ventilation to the cavity behind. In the unlikely event that any driving rain or storm weather should get through the gap in the board, it may hit the weathertight RAB/FAB and trickle out the bottom of the cavity, through the alloy cavity closers provided – ensuring the framing and house remains dry at all times. The cavity will soon dry out afterwards.

Weathertightness testing was carried out as part of the BEAL appraisal, ensuring that the bamboo X-treme cladding system met the NZ Building Code E2 requirements.

Some “backyard” testing of our own, which involved spraying a water hose at full force at the installed cladding resulted in only a little water getting through the gaps between the boards – but the cladding absorbed the water pressure with minimal water trickling down the back of the cladding boards (and out of the cavity closers at bottom of wall). Any splashing would simply hit the RAB/FAB and later dry out.

Absolutely. The cladding can be used for recladding over existing weathertight cladding, if required.

Sustainability

The Moso bamboo species that our bamboo products are made from comes from fully renewable forests, where it is selectively harvested annually. Because of the exceptionally fast growth, Moso bamboo is managed as an agricultural crop: the annual harvest of the 4-5 year old stems (compared to 60-80 years for tropical and other hardwoods!) – provides a steady annual income to farmers and stimulates the bamboo plant to reproduce even faster. Therefore, in contrast to tropical hardwood, there is no deforestation taking place for production of our bamboo products.

Bamboo is therefore a rapidly renewable resource, in plentiful supply (there is over 7 million hectares of bamboo grown in China).

The Moso bamboo plant consists of multiple stems. As a result, several stems may be harvested each year without killing the mother plant.

Bamboo also holds carbon dioxide in its root system. Research has shown that compared to trees and other plants, bamboo is much more efficient at dealing with atmospheric CO2 which is good news for climate change.

There is more CO2 absorbed during bamboo’s growth, than what is given off during manufacture and transport, therefore the resulting products are negative CO2.

Bamboo is considered a top environmental choice by architects, builders, homeowners alike.

Our bamboo X-treme cladding is made from the Moso bamboo species (Phyllostachus Pubescens) – which grows in China. The giant bamboo is the backbone of the Chinese bamboo industry.

We source all of our bamboo products from MOSO Bamboo, a Dutch world-leader in bamboo innovation, who contract out the production of the cladding to a leading factory in China – made to stringent specifications. MOSO has a large team of specialists in China carrying out Quality Assurance testing and production management.

Bamboo also holds carbon dioxide in its root system. Research has shown that compared to trees and other plants, bamboo is much more efficient at dealing with atmospheric CO2 which is good news for climate change.

There is more CO2 absorbed during bamboo’s growth, than what is given off during manufacture and transport, therefore the resulting products are negative CO2.

Bamboo is considered a top environmental choice by architects, builders, homeowners alike.

More information on bamboo and sustainability here.

Some people have expressed concern that the natural habitat and food supply of Pandas will be harmed by bamboo product manufacture. There are well over 1000 species of bamboo, and the type used for our products, the giant Moso bamboo (Phyllostachus Pubescens), is very different to that sought by Pandas and the manufacture of our products has no negative impact on the Panda’s environment.

Installation

No. Most customers don’t tend to apply the end-grain sealing wax, but our supplier MOSO Bamboo does recommend it being applied to the cut ends of boards. You can normally purchase end-grain sealing wax from large hardware stores like Mitre10 or Bunnings.

You could use a product like Metalex timber preservative (or something similar). This product would only need to be applied on the cut ends of the boards, not if you were to rip the boards down to size (lengthwise).

The cladding boards are all 1850mm (long) x 137mm (wide) x 18mm thick – and with overlapping of the boards when installed (and clipped together) provide an effective cover of 128mm.

The cladding is sold in boxes of 5 boards = 1.184sqm per box (giving 9.25 lineal metres) – and supplied with 25 clips and 50 x 50mm screws (for 20mm cavity installation).

We supply special alloy cavity closers as part of the “bamboo X-treme cladding system”. These cavity closers are strong, 1mm thick aluminium, made to support the weight of the bamboo cladding. The “U” shaped closer is normally used at concrete slab level (and is also a vermin strip) and the “L” shape closer is normally used above windows and doors, where the cladding boards are ‘rebated’ onto these closers to hide them from view when looking up.

The alloy cavity closers come in 1800mm lengths, in the following profiles:.

Type 3 (product code PB3H) – for 20mm cavity – for horizontal or vertical board installation- where bottom of closer is “U” shaped – please see drawings (often used at the bottom of a wall at slab level and hooks into the female groove on the cladding)

Type 4 (product code PB4V) – for 20mm cavity – for vertical or horizontal board installation where the bottom of the closer is “L” shaped – please see drawings (often used above windows so that the cavity closer is not visible from underneath).

The cladding can also be installed over a 10mm cavity, if preferred (the BEAL Appraisal Certificate covers 10 or 20mm cavity installation) – and there are two cavity closer options available for a 10mm cavity (available on request).

Yes, if required. Some “traditional” window and build processes may still require window head and/or jamb flashings. We have the technical drawings for these in our Technical Manual.

The bamboo X-treme cladding system (which has been tested and appraised against the NZ Building Code by BEAL) is only appraised as being installed with the approved clip and screw fixings supplied with the cladding – not with direct fixings through the boards.

However, as part of the standard vertical cladding installation there is a requirement to screw through the board at the first batten above any cavity closers with one x 75mm stainless steel screw (per board). This is to reduce any risk if there was a major seismic event to prevent a vertical board potentially coming off the closer in extreme shaking.. Please see technical drawings for more detail.

Customers may choose to use the bamboo X-treme cladding in other projects like fencing, screens or similar by direct-fixing the cladding boards, as needed.

No. The bamboo X-treme cladding system has been appraised as being installed over a 10mm or 20mm cavity on top of a RAB or FAB (rigid/flexible air barrier – that has been taped or wrapped), which provides the required weathertightness. This system then effectively provides two layers of weather protection to the home.

Cavity battens should be a ventilated type – either fluted plastic (like “Cavibat” battens) or castellated – to create proper air circulation and minimise any moisture build-up within the cavity.

Scribers can be made (as required) from ripping/cutting the bamboo X-treme cladding boards.

For vertical installation of the cladding, the spacing of the cavity battens is 462mm, so that the ends of each board join over a batten. Therefore, some extra dwangs or nogs may be needed to achieve this requirement.

For horizontal installation standard 600mm (maximum) spacing of studs and cavity battens is permitted, as it is not so important to have the boards join over a batten.

Please see the technical drawings for more details around the assembly process.

Yes, providing structural timber battens are used, so that the bamboo X-treme cladding can be securely screwed onto the battens (that are securely attached to the framing).

Installation should be carried out by someone experienced with cladding systems and following the Technical Manual. For code-compliant installs (especially for consented builds), a licensed builder is recommended.

Durability

As the bamboo x-treme cladding naturally weathers it will silver off over time and the attractive bamboo grain becomes more apparent. However, you can easily oil the cladding to a preferred colour at any time, if desired.

The bamboo X-treme cladding is considered low maintenance as you can just leave it to weather (it does have a 25 year structural warranty even if left to weather naturally).

Our bamboo x-treme cladding is very hard, durable and stable, so it handles the extremes in our NZ climate extremely well. A key reason for this is due to the special “Thermo density” heat-treatment production process.

This patented process is used to enhance the hardness, dimensional stability, fire safety and durability to a level superior to the best tropical hardwood species. During the heat-treatment process all living micro-organisms and sugars are removed preventing rot and mould being able to develop over time.

The cladding is made in a similar process to our bamboo x-treme decking, which has been well proven in all NZ environmental conditions over the last 10 years or so – with great feedback from builders and customers (see Google reviews).

Due to the manufacture process and density of bamboo X-treme cladding it does not tend to buckle, warp or crack to the extent of some other timber cladding options. This results in straight vertical/horizontal lines with the bamboo x-treme cladding system.

Over time, some cracks on the surface and/or ends of the boards can arise from the different drying characteristics of the surface and cross-cut ends. This normal phenomena does not affect the stability or durability of the board. The surface of the boards will tend to get a little rougher over time and may form some splinters or cracks as a result of continuous water absorption and desorption due to dry and wet weather periods.

Dimensional change or cupping of the boards can sometimes occur after installation, but less so than most timber products. The above phenomena are normal for most hardwood species (and bamboo at times).

However, any rough patches or surface cracking can normally be quite-easily smoothed off with a light sanding or brushing – this is best done prior to oiling the cladding too.

The fixing clips provided are powder coated stainless steel (grade 304) , so are suitable to be used on or near coastal properties without fear of rusting. The screws supplied are stainless steel also.

Bamboo X-treme cladding has a 25 year structural warranty (see Warranty here), so will last many years. Although being relatively new to the New Zealand market, the cladding has been extensively used and tested in Europe and other countries for over 10 years. The cladding is made the same way as our bamboo X-treme decking, but with a shiplap cladding profile added. Bamboo X-treme decking has been well proven in all NZ environmental conditions over the last 10 years or so – with great feedback from builders and customers (see Google reviews).