Bamboo X-treme Cladding Installation & Care Instructions

Introduction

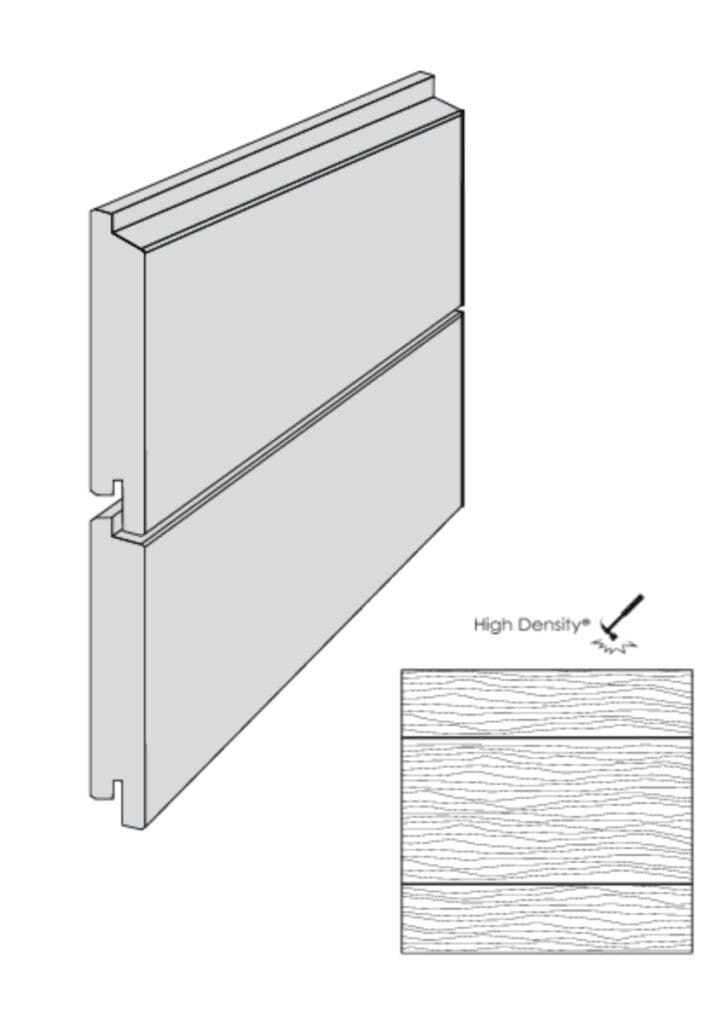

Bamboo X-treme Cladding is a high density, stable and durable cladding product, that comes with powdercoated stainless steel clip and screw fixings for “invisible” fastening. This cladding has been tested and appraised by BEAL as being compliant with the New Zealand Building Code.

The bamboo x-treme cladding boards are 1850 x 137 x 18mm in size with the visible width of the board being 128mm once installed (due to the overlapping profile of the boards). The ends of the boards snuggly connect with an end-matching tongue-in-groove join.

Click here

For Installation Instructions and the Technical Manual

Important Information

The Bamboo X-treme outdoor cladding board is a natural product, some variation in colour, grain and appearance is normal. The colour is likely to change from the original darkish brown to a lighter brown or silver-grey colour over time, depending on the sun/UV and climatic conditions, along with the maintenance schedule.

Small cracks and splinters on the surface and on the board ends can arise from the different drying characteristics of the surface and ends. The surface will also become rougher over time. This phenomenon is normal for most wood species and is minimised for this product through the unique ‘Thermo-Density®’ production method. Cracks on the cut ends of the boards can be further minimized by applying sealer.

Slight dimensional changes or cupping of the boards can occur after installation. This phenomenon is normal for most wood species and is minimised for this product through the unique “Thermo-Density®’ heat treatment production method. Keep the ventilation gap between the boards, that the clips provide. Installation with the stainless steel powder coated clip ensures correct spacing automatically.

Due to the stability of the boards and the shape of the end-match system, no expansion gap is needed where the boards connect with each other. It is recommended applying a sealer on every (cut) end to prevent water penetration. This can normally be purchased from your local hardware store.

Cleaning and Maintenance

You can leave the cladding without any oiling/maintenance, but take into consideration that without maintenance and oiling the cladding will develop more of a rougher, fissured surface that will lighten quicker and become silver grey over time, as it weathers (similar to most timber products).

If you want to keep a darker colour, the application of WOCA or Sikkens (or similar) oil maintenance material is needed:

- Clean the cladding with water.

- Let the cladding dry.

- Smooth off any rougher areas with a stiff brush or light sanding.

- When the cladding is completely dry and clean, apply the finish according to the supplier’s instructions.

Normal Phenomena

Cracks on the surface and on the ends of the boards can occur due to the different drying characteristics of the surface and board ends. This does not affect the stability or durability of the board. The surface side of the boards will become rougher over time and can form (small) splinters as a result of continuous water absorption and desorption due to dry and wet weather periods.

Dimensional change or cupping of the boards can occur after installation. These phenomena are normal for most hardwood species and Bamboo X-treme cladding. After installation, there may be some minor bleeding or leaching of colour from the bamboo material when it gets wet eg. when it rains.

This possible bleeding is typical for most wood products and will disappear over time. The brownish liquid can easily be cleaned from the Bamboo X-treme cladding material, however controlled water drainage and prevention of splash water is required to prevent any discoloration of surrounding or underlying building components.

Storing

Store Bamboo X-treme cladding in a cool and dry place away from direct sunlight, and protected from the weather, dirt and dust.

- Density: +/- 1150 kg/m3

- Dimensional stability: length: + 0.1 %; width + 0.9% (24 hours in water 20°C)

- Resistance to Indentation – Brinell Hardness: ≥ 9.5 kg/mm2 (EN 1534)

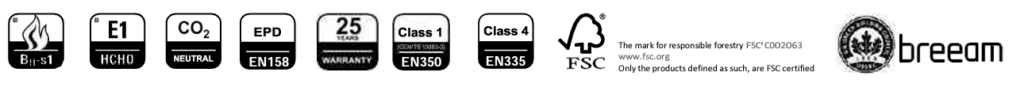

- Reaction to fire: Class B-s1-d0 (EN 13501-1)1

- Flame Spread Index: Class A (ASTM E84)

- Thermal emittance: 0.81 (ASTM C1371)2

- Solar Reflectance (SR) : 0.32 (ASTM C1549)2

- Solar Reflectance Index (SRI): Low 27, Medium 30, High 33 (ASTM E1980)2

- Modulus of Elasticity: 13565 N/mm2 (mean value – EN408)

- Bending Strength: 54.4N/mm2 (characteristic value – EN408)

- Biological durability: Class 1 (EN 350 / CEN/TS 15083-2), simulated graveyard test; Class 1 (EN 350 / CEN/TS 15083-1)

- Effectiveness against Blue Stain: Class 0 (EN 152)

- Use Class: Class 4 (EN 335)

- CO2 neutral: LCA report TU Delft (ISO 14040/44) (www.moso-bamboo.eu/lca)

- Environmental Product Declaration – EPD (EN 15804) (www.moso-bamboo.eu/epd)

- FSC®: Products may be available with FSC® certification on request.

- Contribution LEED BD+C – v4: MR 1, MR 2, MR 3 (FSC®) SS 7 v2009: MR6, MR7 (FSC®)

- Contribution BREEAM: MAT 1, MAT 3 (FSC®), MAT 5 (HD)

- Plantation offers a 25 year warranty on our Plantation Bamboo X-treme® cladding (see warranty on website)

1 Tested on 18mm thickness, without gaps between boards, with ventilation space behind boards

2 Tested on 3 years weathered Bamboo X-treme®